Bikes and Builders of the MADE Bike Show: Part Two

Share This

Our MADE Bike Show coverage continues with a second roundup showcasing 10 more stunning bicycles and the builders who created them. Learn more about the bikes, meet the people behind them, and find a selection of photos highlighting their handmade details here…

The mix of new and veteran bike builders at the MADE Bike Show was fascinating to see. It seemed like every other builder I spoke to took a framebuilding course a few years ago, started a bike company, and dove head first into producing beautiful bikes ever since. In many ways, I think we have the pandemic to thank for this recent influx of wickedly talented new builders. On the other side, there were builders who have been at it for decades using the event to show off their techniques and unmistakable experience. The best part was how everyone mixed together. It wasn’t a matter of builder versus builder. Rather, it was a collective celebration of their art.

Following part one of our bikes and builders roundup, we’re back with 10 more bicycles and stories from the builders who made them. This time around, we’re showcasing bikes from Bender Cycles, Manzanita Cycles, English Cycles, Neuhaus Metalworks, Sklar, RollingDale, Rodriguez Bicycles, Destroy Bikes, and Blaze Bicycles. Find them all below.

Manzanita Cycles link

Reno, Nevada

Nick Jensen started Manzanita Cycles in Reno, Nevada, in 2019, but it initially started as a hobby after taking a framebuilding course with Doug Fattic in Michigan. In those days, Nick used his new skills to make bikes for himself, friends, and family. It wasn’t until he wanted to build touring bikes that he really got into framebuilding. More specifically, he wanted to build a touring bike for his honeymoon in New Zealand, but it unfortunately didn’t get back from paint until after they had left. Once they made the move to Reno, Nick had a proper workshop and enough space to feel comfortable making and selling bikes to others. Manzanita Cycles was born.

Nick’s Ultralight Hardtail

Weighing in at a scant 19.7 pounds (8.9 kilograms), Nick’s ultralight hardtail is designed to be both a gravel bike and cross-country mountain bike. It has pretty conservative geometry and a short front centre compared to Nick’s trail bike, but he wanted flat bars for better control on rough descents. “There’s this website called the Most Dangerous Roads, and they have a list of the highest roads in each state. They have a list for maybe 20 or so roads in Nevada, most of them are off-road and are above 10,000 feet. My goal is ride all of the highest roads in Nevada using this bike.”

In an effort to experience it for himself, the bike is equipped with SRAM’s latest UDH transmission, but Nick said he probably won’t use it like that. Still, he felt it was important to have a first-hand opinion for his customers. It’s set up with Zirbel shifters with are wired through the handlebar to the SRAM eTap AXS BlipBox. These nifty little twist shifters are incredibly low-profile and have a light action controlled by magnets. It was my first time seeing them in person, and Nick and I agree that they feel pretty solid.

Rigid Mountain Bike

The customer who purchased the rigid mountain bike is a shredder, so Nick pushed out the front end like a modern mountain bike. It’s made for 27.5 x 2.6″ tires but has clearance for even more rubber, long chainstays to accommodate rear panniers, and although the owner has a short inseam, they were able to fit a 160mm dropper post to get properly rowdy.

English Cycles link

Eugene, Oregon

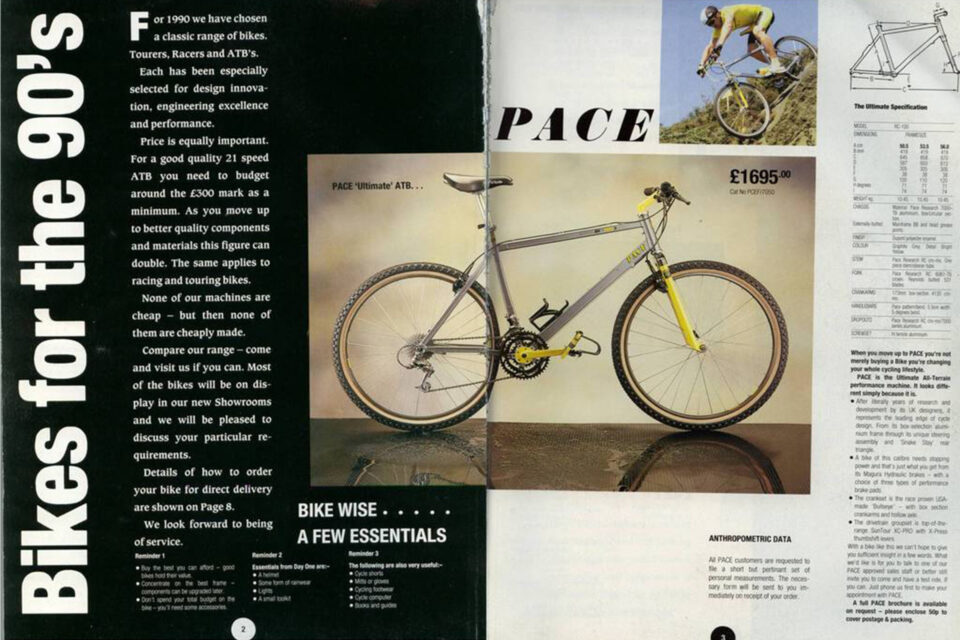

English Cycles is owned and operated by Rob English in Eugene, Oregon. Rob bought his first Mountain Bike Magazine in October of 1988 just when he was getting into mountain biking. In the magazine, there was a bike test of the Fat Chance RC-100, complete with aluminum squared tubing, an upside-down stem steerer, and many other details that Rob believes were so far ahead of their time.

Pace EC-100

Rob set out to make a modern interpretation of the original RC-100. It’s built out of square steel tubing instead of aluminum, so that’s what Rob works with. His interpretation has a more modern geometry and parts than the RC-100, but it also has an original Pace fork crown that he found on eBay, which perfectly suits the build.

When I asked Rob if there were any details he was the most proud of, he said, “The entire thing is incredibly weird. It has a one-piece stem/steerer, so the headset is adjusted from underneath the fork crown. It has super short chainstays and the single straight piece of steel used for the chainstays results in a lot of tire clearance. It’s is something I might start using on regular bikes.”

Neuhaus Metalworks link

Novato, California

Neuhaus Metalworks is a two-person operation based out of Novato, California. Nick Neuhaus is the founder, fabricator, and designer and owns the fabrication shop where all of their frames are made. Daniel Yang is a designer and engineer and is responsible for all of their 3D printing, which is something they’ve been leaning into heavily. They currently have four models in their lineup: two drop-bar bikes and two hardtail mountain bikes. They also offer 100% custom frames and geometry for those who want it.

Hummingbird

The Hummingbird is their most popular production model, which is offered in both titanium and steel. A few interesting features include room for two bottles within the main triangle, even on the extra-extra-small frame. There’s also a bottle bracket on the seat tube that allows for longer dropper post insertion while also angling the bottle forward to create more clearance for larger bottles.

Every Hummingbird comes with a 3D-printed top tube/seatstay yoke, chainstay yoke, and dropouts. “I can confidently say that we have more 3D-printed parts out in the world on bikes than anybody else in the last two years,” explained Nick. They originally 3D-printed everything themselves but because they are making 500 at a time these days, they’ve outsourced it. Even the cable ports are 3D-printed, which create a cohesive unit that eliminates cable routing inside the frame.

Because Neuhaus is in complete control of the entire process, they can customize the materials and design to fit specific needs. Nick used the example of someone looking to get a bike that priorities ride quality while loaded up with bikepacking gear and how they can tweak the design and construction of each part to achieve a goal. The 3D-printed yokes are size-specific and tuned specifically for that frame.

The story of how Nick made to switch from an 18-year career as a telecommunications engineer is a heartwarming one. “I walked in the house and my son looks at me and he goes, ‘Dad, what’s wrong with your face?’ He was five years old. ‘It just looks so sad and droopy.’ Nick explained how at work he has meetings with people who don’t care about him or anyone else, only about money, and he has to do the same thing again tomorrow. His family encouraged him to make a change, and almost two years and 200 bikes later, Neuhaus is thriving. Learn more about the Hummingbird here.

Sklar Bikes link

Bozeman, Montana

While working on an engineering degree, 18-year-old Adam Sklar started building steel bikes in his parents’ garage with tools from the local hardware store. Sklar Bikes was born a couple years later as Adam lived out his obsession with building frames for friends, then friends of friends, and ultimately strangers. Sklar was won several framebuilding awards since then and has expanded his offerings to include production models with stock geometry released in small batches. He had both of his current stock options on display over the weekend: the Tall Tale hardtail and the Super Something gravel bike. We just picked up the latter to review, so we’ll report more on that soon.

Tall Tale

The Tall Tale is Sklar’s latest prototype of a new production model that is coming early next year. It’s based off of their late Sweet Spot platform but with a new name and some fresh features. The final version will be made in Taiwan, although the prototype on display was built at Adam’s shop in Bozeman, Montana. The Tall Tale is a progressive hardtail mountain bike, designed for 130-150mm of travel, clearance for 29 x 2.6″ tires, a 73mm threaded bottom bracket, and three sets of bottle mounts. You can learn more about it here.

Roly Poly Coffee Cargo Bike

One of Sklar’s neighbours is Montana’s only coffee shop and bean roastery, Roly Poly Coffee Co. Taylor, the owner of Roly Poly, quickly became friends with Adam after moving to town, and they’ve collaborated on several projects together. Brooks approached Sklar about making a bike for MADE, and Adam thought it was the perfect opportunity to make a custom cargo bike bean delivery rig for the coffee shop. Iit’s a cycle-truck-style cargo bike with a compact cargo platform built into the frame, with a 29″ rear wheel and 24″ front. And how ’bout that Brooks B190 saddle?

Bender Bicycle Co. link

Fort Collins, Colorado

Some of my memorable moments from MADE were spent chatting about non-bike-related things. Bikes are the obvious common ground for most of us at the event, but finding something beyond them made for more genuine interactions. William Bender, owner of Bender Cycles, and his wife Trinity somehow ended up chatting about house sitting as an affordable way to visit new places. Emily and I have been house sitting on and off for a number of years now, and I was stoked to share my experience with them. I think they’re sold on it. But back to Bender’s bikes.

The Hardtail

Bender Cycles is a custom framebuilder based in Fort Collins, Colorado. With support from his wife, William designs and fabricates his frames in-house, fueled by a background in design. They offer two production models: a hardtail mountain bike called The Hardtail and an all-rounder called the Master of None. According to William, The Hardtail blends “innovation with the comfort of familiarity,” making it suitable for quick day rides and long-distance adventures. Bender offers custom two-color paint jobs, frame-only or complete builds, and totally custom geometry and specs.

Master of None

“Master of None seamlessly shifts from everyday tasks to exhilarating trailblazing, capturing the essence of early mountain biking while embracing contemporary advancements.” A true ATB, the Master of None that Bender had on display at MADE was easily in my top three favourite bikes. There’s something about its clean lines, speckled paint job, and functional build that has me thinking it would be a fantastic everyday bike.

RollingDale Cycles link

Fort McMurray, Canada

Dale, the owner of RollingDale Cycles, grew up in Fort McMurray, Canada. He worked in and out of industrial shops most of his life with a lot of time in the oil and gas industry. He learned how to weld in high school, and it ended up being something he thoroughly enjoyed. “My dad always had a workshop at home—more woodworking—but I never fell in love with wood. As a medium, I always liked metal,” he said. In 2015, Dale took a framebuilding class with Paul Brodie but was put off by the amount of tooling and material required to start. Over the next few years, he honed his skills, learned to build titanium frames, and eventually was at a point where he felt comfortable building frames for his community. However, made the decision not to compete with other framebuilders. Dale wasn’t, and still isn’t, interested in generating a competitive landscape.

The Silver Dagger

The Silver Dagger is named after the Callahan Brothers’ 1934 folk tune. As a fan of old bluegrass music, he found the song’s storyline fitting to name a bike after. The Edmonton River Valley, where Dale rides, is steep and pitchy, and the bike is designed for those often gnarly and technical trails. It has a long front centre for stability on technical climbs and descents, 425mm chainstays with room for a 29 x 2.6″ tire, and a 66° head tube angle (sagged). Thanks to a high stack and his own 65mm riser bar, Dale finds the fit to be incredibly comfortable. The lower top tube was added to help integrate a half frame bag for day rides, giving Dale the ability to easily carry extra layers and snacks. The bike has a titanium bash guard, a titanium seat collar, and a Bentley Components top cap.

Curious about RollingDale’s head tube badge? I sure was. It turns out it’s a depiction of Dale’s hand giving a thumbs up, but Dale has a crooked pinky that sticks out awkwardly from his hand. “It’s kind of weird, but it should be weird,” he explained.

Rodriguez Bicycles link

Seattle, Washington

Seattle-based Rodriguez Bicycles has been around since 1973 and just recently celebrated their 50th anniversary. The have always welded and painted in house, as Alder Threlkeld, one of the co-owners explained. Rodriguez Bicycles has an extensive lineup of road and gravel bikes, but also specializes in tandems right up to five-person, extra-long bikes. They are proud to work on weird bikes that aren’t necessarily made by them. “We made a five person tandem for Rick Ross, the rapper, but we also get a lot of other tandems in and other bikes that are too weird to bring to a normal bike shop,” Alder explains.

6-Pack

The 6-Pack was inspired by European travellers facing travel restrictions on trains. It has six couplers, allowing it to pack down into a Samsonite carry-on suitcase. Almost all the tubes disassemble into individual parts. The seatstays come apart from the chainstays, the top tube and head tube stand alone, and if you’re traveling with a friend, they offer a tandem version called the 2014 with 20″ wheels and 14 couplers.

Rodriguez Bicycles employs seven people including Alder and has positioned itself as being slightly out of the ordinary. Although they’re still working on getting their name out there after 50 years, they’re clearly passionate and happy to be working with weird bikes.

Destroy Bike Co. link

Portland, Oregon

Destroy Bike Co. is a custom bike brand based out of Portland, Oregon. They started out building track and tracklocross frames, but they also build geared bikes. The team consists of three friends who founded the company in 2011 down the coast in Redwood City, California. They moved north to Portland five years ago and usually drop a small production batch of frames every now and again in addition to offering full-custom builds.

Adventure Klunker

The Adventure Klunker was designed for a friend looking to crush commutes and also get outside and camp with. It features house-built handlebars, a custom yoke, a segmented fork, and in-house paint. They are also looking at releasing some cyclocross frames for the upcoming season, so make sure to keep an eye on their website to learn more.

Blaze Bicycles link

Portland, Oregon

Pierre Chastain founded Blaze Bicycles in search of better bicycles after spending 10+ years in the visual effects and animation industry. It started by offering custom titanium bikes to the community in Moab, Utah, and slowly expanded to include international customers as well. Pierre does his best to fabricate everything himself and has been making more components on his CNC machine. “It’s really fun to be able to make most, if not all, of the components that go into my frames, as well as some parts for the larger bike industry.” Pierre has also been working on making stems, seat post collars, and a few other bits and pieces that he’s excited to share.

Pinion Adventure Bike

A customer came to Blaze seeking the ultimate bikepacking rig, and the Pinion-equipped hardtail pictured here was the result. The customer was a super bike nerd and did his research to figure out everything he wanted, including the Pinion gearbox, Lauf fork, and integrated rear rack. It has a custom titanium handlebar, a dynamo light setup, and the ability to switch to a conventional suspension fork if the customer wants to. “I’m really proud on how this bike came together,” he said.

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.