Inside Rohloff: Legendary Internal Gear Hubs

Share This

While bikepacking around Europe this spring, Joshua Meissner made a stop at Rohloff headquarters in Hesse, Germany, to tour the space where their iconic internal gear Speedhub is made. Learn more about the beloved company’s past and present and take a photographic tour of their production and repair processes here…

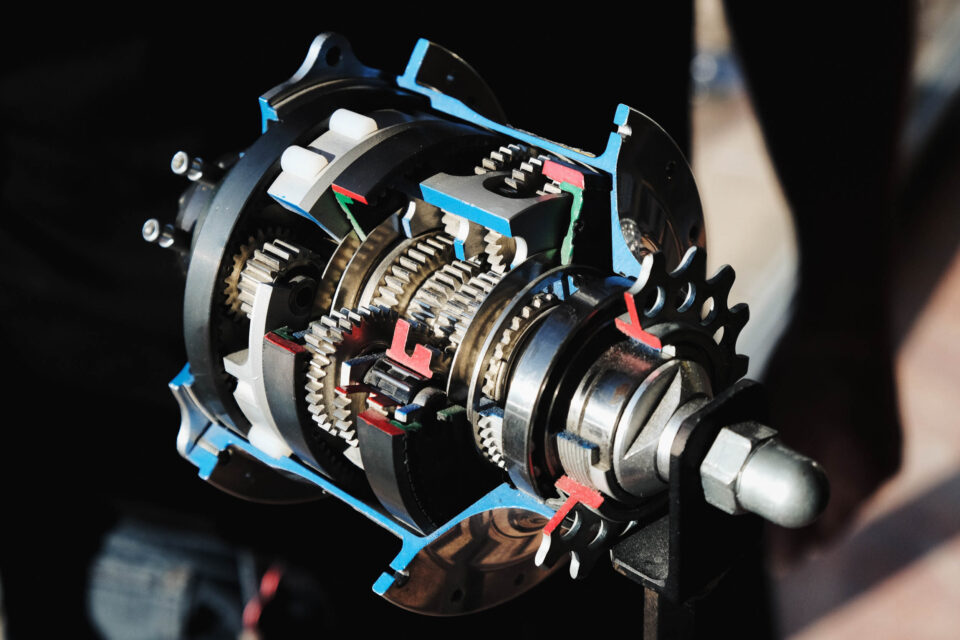

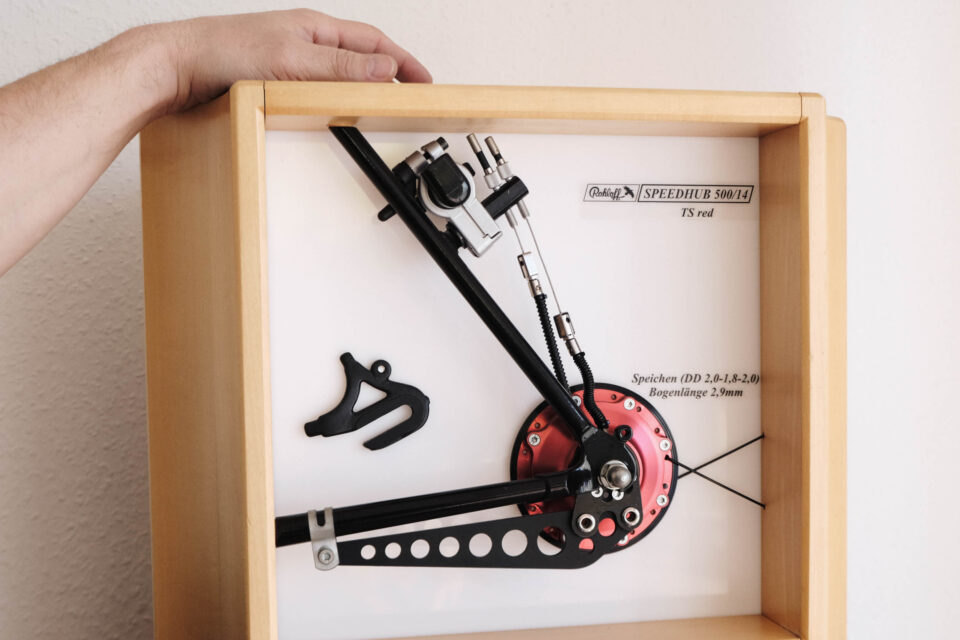

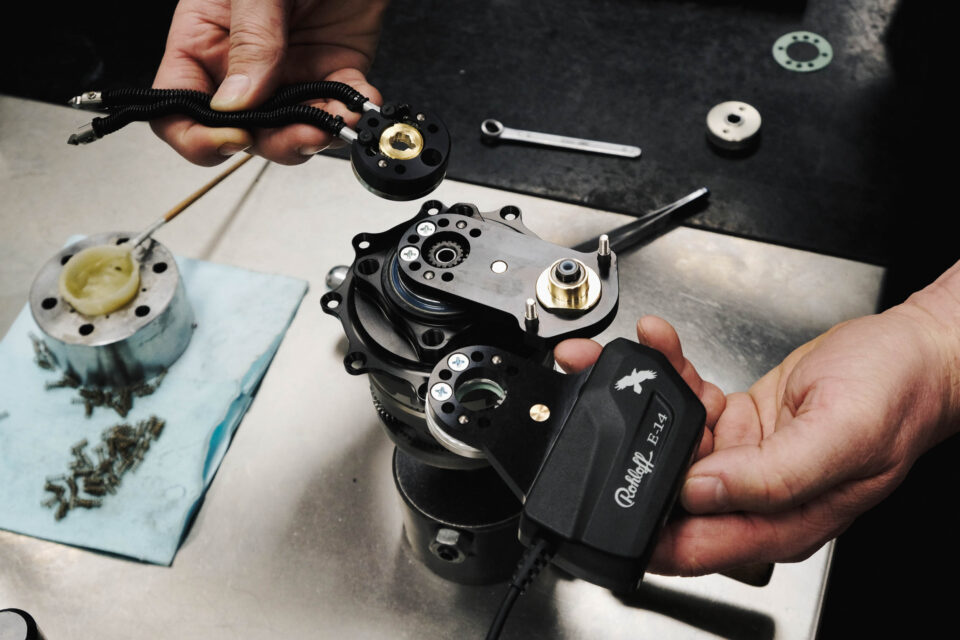

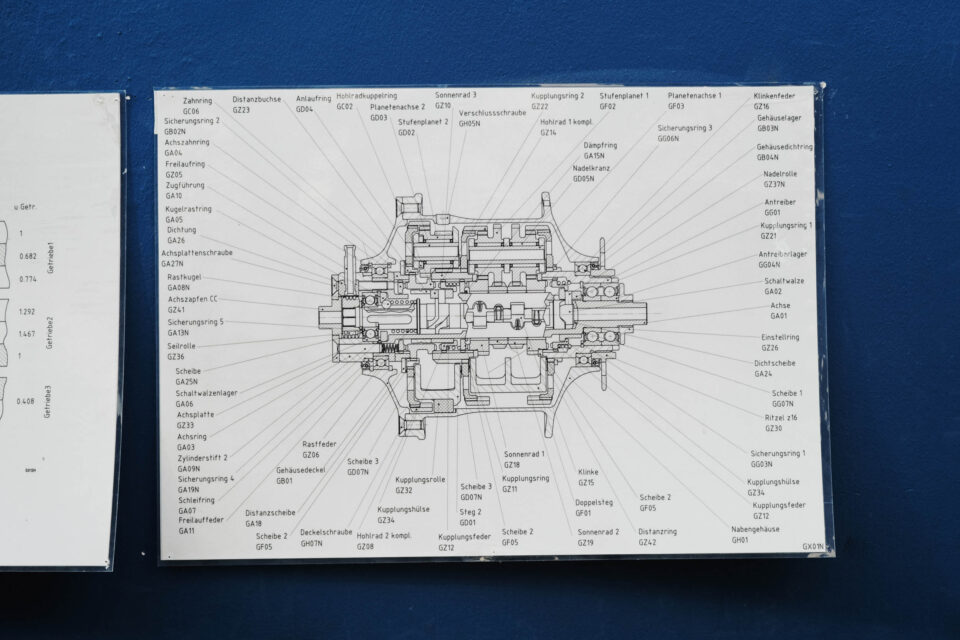

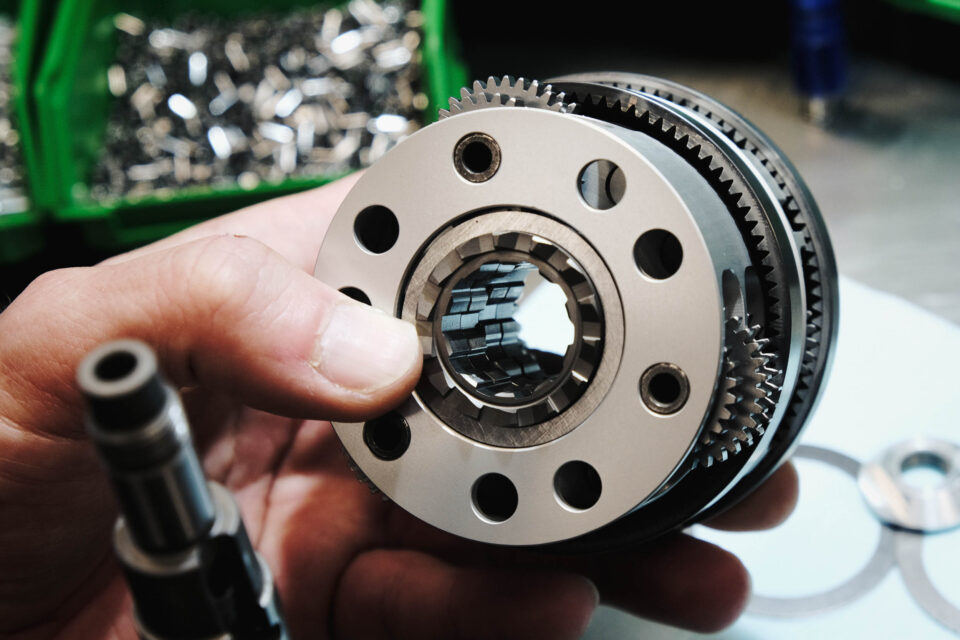

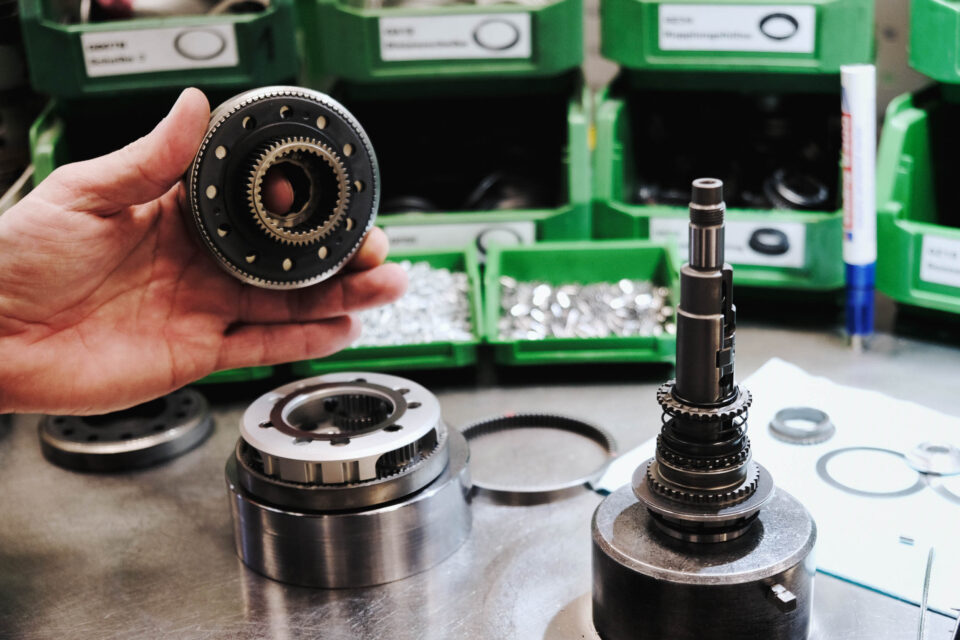

If you’ve spent any time researching suitable bikes and drivetrains for long-term travel, the odds are good you‘ve come across this sage piece of advice more than once: “Just get a Rohloff.” Likely a bicycle touring veteran, the person offering this counsel is talking about the one and only Rohloff Speedhub internal gear hub. With 14 gears, the intricate planetary arrangement of cogs, cams, push rods, and lock rings is protected from the elements and whatever may be encountered inside a tough aluminum shell that sits at the center of the rear wheel. Perhaps overbuilt by modern standards, the German-made Speedhub has been propelling intrepid adventurers and power commuters alike all over the world for more than 25 years—by all accounts, with stupendous reliability.

Indeed, such reliability is most valued the more and further afield you ride, not only by tourers cruising down the Pamir Highway but perhaps even more so by bikepackers embarking on long adventures far off the beaten track. Though I have little personal experience with the Speedhub (yet), most of the team here at BIKEPACKING.com has toured on a Rohloff-equipped bike of some kind for months or years at a time, all without any noteworthy hiccups to report.

While the up-front cost is undeniably steep, and the shifting system comes with some idiosyncrasies, the all-metal hub has serious heft, and you‘re buying into a proven system that has unflinchingly stood the test of time. Similarly to Schmidt Maschinenbau of SON dynamo hub renown, Rohloff credibly builds their hubs to last, despite their relative complexity. The Speedhub just works (and works). With over 400,000 hubs produced to date, they‘ve had an unparalleled zero reported internal failures in regular use.

Since Rohloff keeps all assembly in-house, the company is also able to provide an extensive service program. Besides straightforward rebuilds to refresh bearings and seals, Speedhub owners can keep their cherished hub rolling with new axles and endcaps to bring them up to the newest brake and axle standards. It’s quite common for Rohloff hubs to move from bike to bike, outliving the frame that initially hosted them.

On my way from Berlin down to Spain earlier this year, I stopped off at the Rohloff AG headquarters, which is located in a typical commercial zone by the city of Kassel in the center of Germany. Like many other hidden champions in the country, they keep mostly to themselves and let their well-engineered products do the talking. Quality ultimately resides in company culture and processes, and it manifests in the product. Touring Rohloff’s assembly area, their obsession with precision was evident at every step.

The incremental improvements they make to their already near-perfected product don’t make big waves at news outlets pushing the latest and supposed greatest, but the measured approach has clearly been good for the company—now counting over 50 employees—and is surely foundational to their reputation of consistent reliability and long life.

I was lucky to get the inside scoop at Rohloff from senior manager Marco, who’s been dedicated to the company since 1996. Starting back then in a marketing role, he now acts as the product manager of the extensive Rohloff product portfolio. The name Rohloff didn’t originally stand for internal gear hubs, so read on for some essential history and details on their quality-oriented culture and processes that got them to where they are now.

Rohloff as a company has been operating for over 30 years, but it didn‘t start with the Speedhub. What were some of the original products made by Rohloff?

The product that solidified our name in the cycling industry was the SLT-99 derailleur chain. We were the first company in the world to offer a 9-speed chain, at which point Campagnolo took an interest and asked us to supply high-quality chains for every Super Record groupset. These chains are no longer available due to the limited supply of quality material. However, we still continue to produce a number of drivetrain tools and measuring gauges to support derailleur and singlespeed riders.

Developing and manufacturing an internal gear hub represents a big jump in complexity compared to even high-end chains and tools—a big risk that seems to have paid off. Which factors gave rise to the development of the Speedhub?

Only one thing, really: the desire to combine the advantages of the derailleur system and internal gear hub in one extremely reliable, sustainable product.

At which rate are you producing the Speedhub today? How is that trending?

Currently, we produce 35,000 units per annum. Our production volume has approximately doubled in the last four years due to the expectations and demands from high-end and heavy-duty e-bike/cargo bike applications.

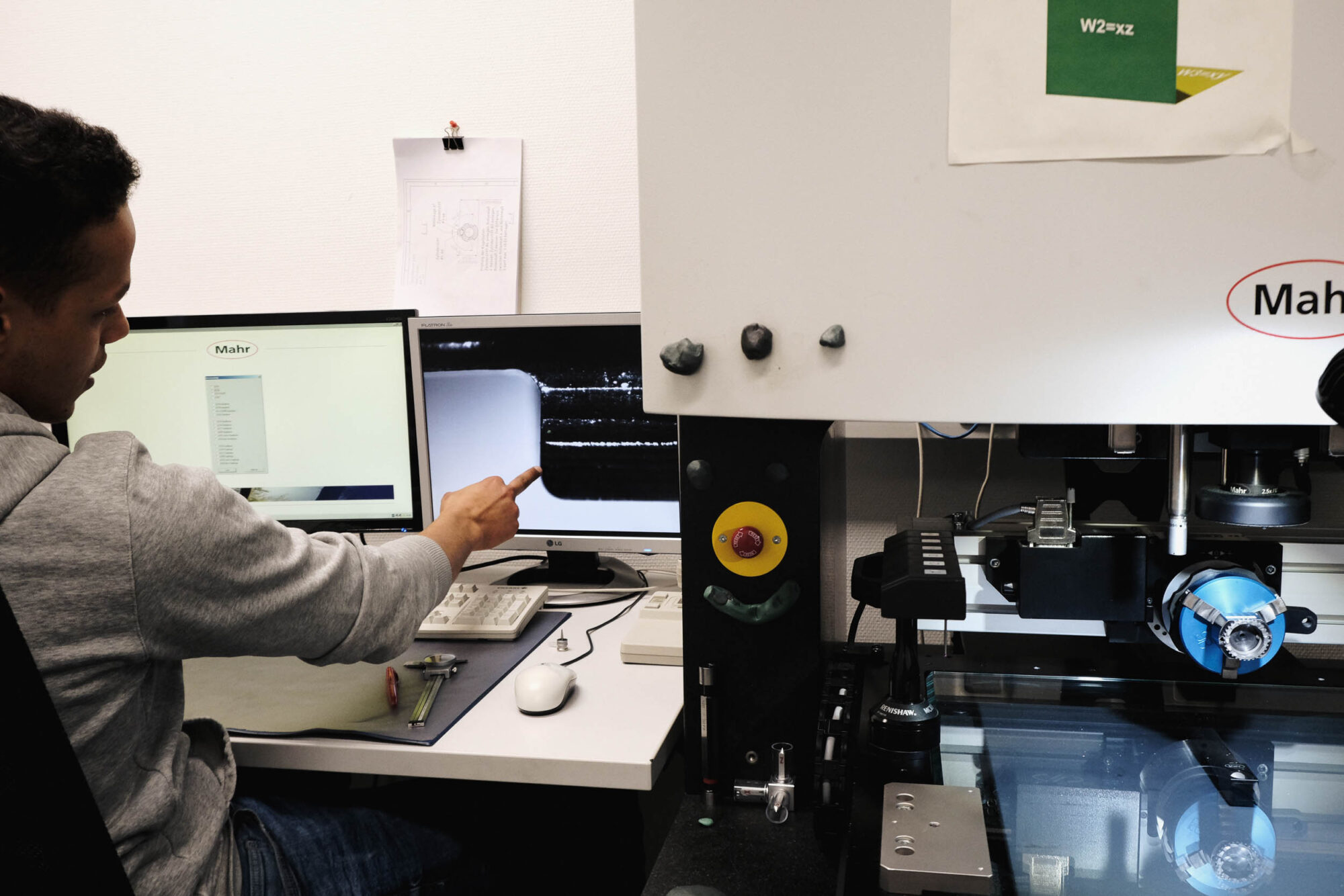

During my visit, I was intrigued to learn that your in-house focus lies on precision assembly, while the complex machining tasks are contracted out to local suppliers. How do you ensure consistently high quality in the final product while working with numerous independent suppliers?

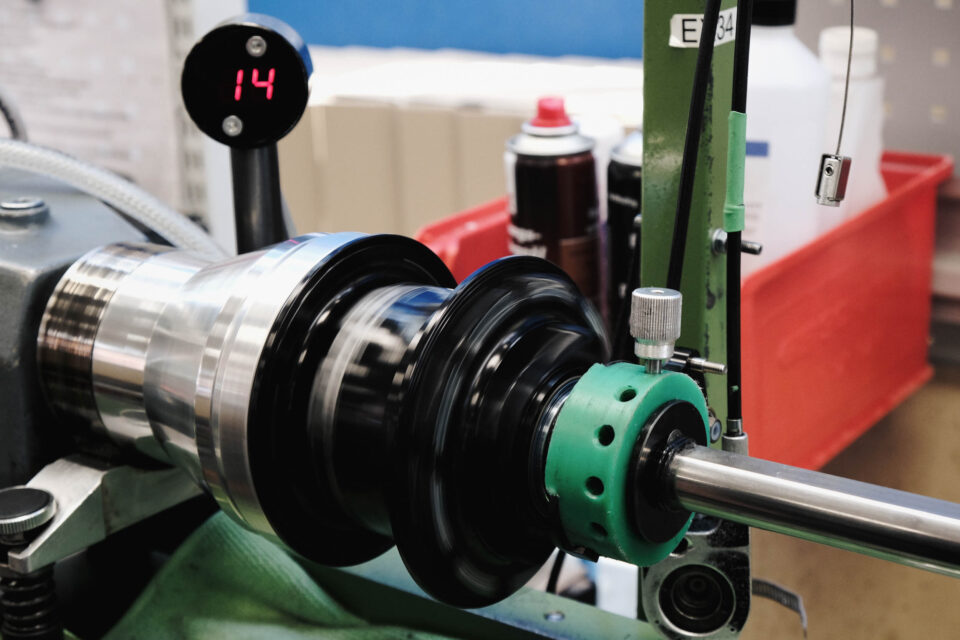

We have extensive quality control via high-tech, computer-controlled machinery, along with manual 100% checks for specific components. These automotive-industry-oriented QC processes are key to ensuring the SPEEDHUB is a 100% adjustment-free product.

There’s a Speedhub for nearly every frame and brake standard, but picking the exact right configuration seems slightly daunting. If I were looking to acquire a Speedhub-equipped travel bike, how would I best go about that?

The best bike is one that’s comfortable and fun to ride. As such, although we offer exceptional tools for viewing OEM, SPEEDHUB-equipped bicycles, we can’t say whether the bicycle most appealing to you will be the best bike for your desired application or demands. So, always advise visiting a local Rohloff dealer to check these aspects. As you mentioned, the ability for a SPEEDHUB to fit in most frames will also enable your dealer to build a custom bike for you, should those online OEM options fail to satisfy your needs. To assist with finding a competent local dealer, we also offer an online dealer locator search engine.

In recent years, a number of competitors to the Speedhub have started crowding the internal gear hub/gearbox space. What differentiates the Speedhub from the rest?

This would be better answered by the “competition,” but Rohloff doesn’t view these companies as competitors. Rather, we see ourselves almost as a team, working together in a strange sort of way, to improve the riding experience for cyclists who are no longer willing to put up with the downsides of traditional derailleur systems.

The derailleur bicycle transmission has come a long way since its initial development, but the fundamental downsides still exist. It is impossible to shift while stationary, and the system is exposed and thus subject to damage. It requires repetitive maintenance and lubrication if used in poor weather, and the constant fluctuating chainline increases primary transmission wear (and, with it, the cost of maintaining a functioning system) significantly.

Naturally, Rohloff would love for customers to choose our products over those of alternative gear-hub and gear-box brands, but as long as those riders choose an alternative to derailleur systems, we can all move forward, improving the general cycling experience and thus the industry as a whole.

As I understand it, the mechanical core of the Speedhub is essentially a mature product. Where is your development activity centered these days?

As you note, the SPEEDHUB is a mature product. The core is essentially the same as when it first hit the market back in 1997—a true sign of how advanced the technology was and how durable the SPEEDHUB is. As such, we see no current need to make extensive changes to the transmission. As mentioned above, though, there is a SPEEDHUB for nearly every frame out there, and our future developments are focused on expanding the compatibility of the transmission with the emerging sectors of the cycle market—whether this be increasing the number of torque anchoring solutions, E-14 e-shift motor integration, or other ergonomic customer demands.

Given the intense focus on quality in your hub production, it seems obvious to draw a connection between Rohloff and Schmidt Maschinenbau of SON fame. Is there any exchange going on between the two companies?

The combination of two quality-engineered German hub manufacturers working together is an enticing concept. While our products do complement a bicycle extremely well, our actual cooperation is limited to marketing events such as sharing expo space and aiding one another with dealer seminars to better educate dealers on how to get the most out of our products.

Any last thoughts you’d like to share with our readers?

While we’re extremely pleased with corporate growth and the increased popularity of our products, it has never been Rohloff’s intention to produce mass-volume products. From the very start, Rohloff has aspired to enrich the cycle market with high-quality, durable products that increase customer satisfaction and enable cyclists to enjoy their passion for cycling. We feel we have come a long way to achieving this goal, but alas, we realize we still have a long way to go, and we look forward to seeing how the market evolves.

Once you start paying attention to something, you start seeing it everywhere. Riding southwest from Germany to Spain this year, I crossed paths with quite a few tourers on Rohloff drivetrains, and they usually appeared in tandem with center kickstands and butterfly bars. It comes with the terrain on traditional European cycle touring routes such as the Camino de Santiago along the north of the Iberian Peninsula or the Eurovelo 8 along the Mediterranean. More surprisingly, I discovered a Speedhub on the blue Surly Ogre of Ernesto Pastor, the heart and brains behind the remarkable Montañas Vacías bikepacking route project. I got to pick Ernesto’s brain about his experiences with his Rohloff-equipped ATB and how it meshes with his riding and route-making, but more on that in another article soon.

What I want most from the heart of the bicycle—the drivetrain—is simplicity and complete confidence so my attention may be focused outward. But recent developments from the Big Three drivetrain manufacturers, nevermind the electrification and car-ification of the bicycle in the industry at large, are on an alien trajectory. We’re inundated with flashy new tech while low-hanging fruit that would meaningfully benefit many bikepackers, commuters, and common cyclists gets systematically neglected. I’m thinking of universal interoperability between road and MTB groupsets, gravel bikes with stock gearing that’s sufficient for mountainous terrain, and maybe longer-lasting chains instead of ever more gears, just to name a few. The gear should serve to further the experience, but the industry is innovating past many riders, and it’s a damn shame.

Gauging Rohloff’s obsession with keeping cyclists smoothly rolling across the planet, they might well be the most rider-focused drivetrain manufacturer out there. The Speedhub is an overbuilt, ultra-robust, high-performance gateway to blissful, unthinking reliability. For sure, there are other paths to attaining drivetrain nirvana. But from what I gathered from the satisfied riders on Speedhubs that I met, the internal gear hub from Germany is about as transparent as gears get.

Sadly, not long after my visit, founder Bernhard Felix Rohloff, who was suffering from Parkinson’s disease, died unexpectedly on Friday, May 19, 2023, at the age of 73. Beyond being an inspiring inventor, he was cherished for the humor and warmth with which he constantly inspired excellence in his co-workers, who carry on his remarkable vision. You can read more about Bernhard and his legacy at Rohloff.de.

Related Content

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.